Product Characteristics

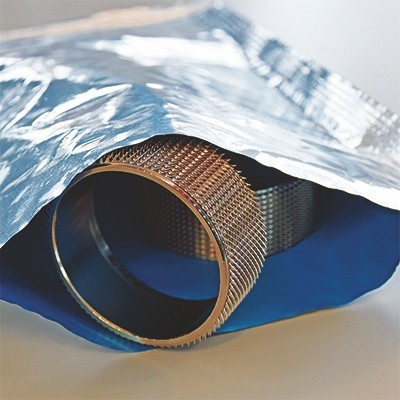

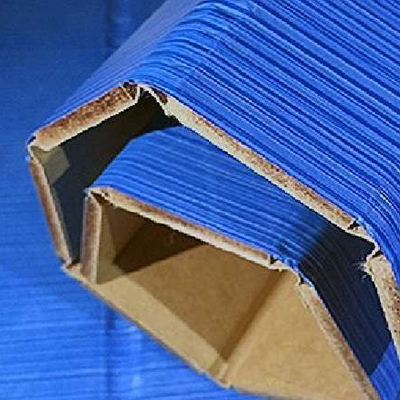

BRANOfol M8 AL is a bluish, nitrite-free special-polyethylene film with active VCI corrosion protection, laminated with a water-vapour-proof barrier foil material. It is weldable and suitable for automatic packing as well as bag production.

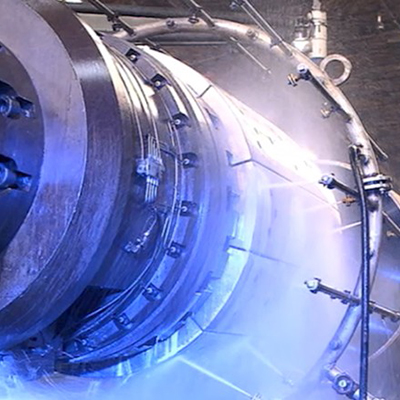

By constantly emitting a small amount of active anticorrosion substances (VCI principle: Volatile Corrosion Inhibitor),BRANOfol M8 AL helps to protect metal parts during transport and storage. Active VCI agents effuse and build up a protecting atmosphere, which protects reliably against rust. Furthermore, the outer barrier foil material prevents the VCI-Inhibitor from escaping and keeps new humidity out.

Duration of Protection

Depending on climate conditions and how well the packaging is sealed, BRANOfol can offer protection for up to three years. The duration of protection can be adapted when the precise application is known.

BRANOfol M8 AL (nitrite free)

Protects steel, cast iron ( on contact ), zinc plated steel, tin, aluminium, zinc,chromium, copper and its alloys reliably against corrosion.

※ For further questions about metals and alloys, our technical support will assist you.

Advantages

· Environmentally friendly corrosion protection without oiling and greasing

· Packaging material and corrosion protection in one

· Metal parts are ready for use immediatly

· Time efficent packaging process

· Easy to dispose and recyclable

· Protects against humidity Non-hazardous material

· Development of customized solutions

Delivery forms

Flat film and other sizes on request.

Storage

Cool and dry, protected from direct sunlight. Shelflife in the original packaging up to three years.

Disposal

BRANOfol M8 AL can be recycled thermally. Dirty films must be disposed by waste incineration.

Operation Safety

BRANOfol M8 AL corresponds to TRGS 615. Please see for further information the safety information sheet.

Application

The packaging should form a closed space so that the best possible utilisation of VCI foil BRANOfol M8 AL can be achieved. The packaging should be sealed closely. Water entering the packaged item should be avoided and has to be kept out.

The surfaces to be protected must be dry and free from corrosionstimulating residues, such as finger sweat and aggressive matter of washing agent, etc. Acids or strong bases interfere with the corrosion protection system. In case of doubt, we recommend a compatibility test to be carried out.

The parts to be protected should not have any direct contact with wood or acidic materials. Atmospheric impurity as well as relative air humidity should be kept out of the package(e.g., no wood parts to be packed together).

BRANOfol M8 AL is processible in mild heat impulse and in separating-seam welding.

If strongly oiled parts are packed, then we recommend the application of non-printed film, since the printing in contact with oil can possibly be solved.

Please pay close attention to thickness and impermeability to water vapour when selecting your VCI films. Both of these parameters are of decisive importance for corrosion protection and should therefore be selected with the specific application in mind.

All of the information contained herein is based on current knowledge and is not binding. Modification may be necessary to suit conditions at the location of use. No claims for damages can be made in this regard.

滬公網(wǎng)安備31011702005477號

滬公網(wǎng)安備31011702005477號