Univeral Forming and Cutting Oil

√ Cutting √ Forming

Product information

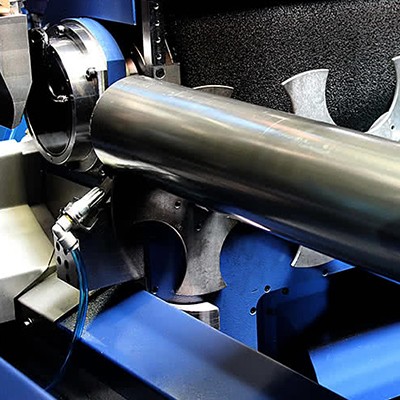

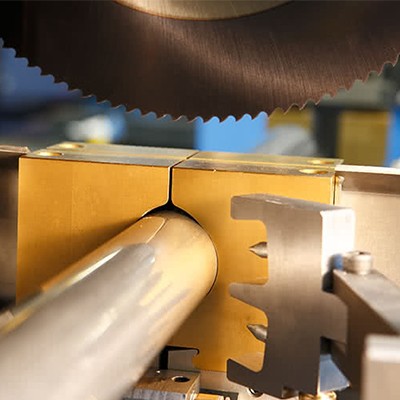

WEDOLIT N 52 is a highly additivated forming-and cutting oil for deep drawing-, extrusion punching- and cutting operations. The product is not onlv suitable for automotive- but also for ferritic- and high-strength chromium-nickel steel. It is applied undiluted by spraying, flooding or by means of a brush or a roller.

Approved by Rattunde & Co as a cutting oil for minimum quantity lubrication.

Properties

· Offers an extremely pressure resistant film

· Outstanding load carrying capacity

· Due to the chemical additivation, a long-termed corrosion protection is dependent on the treated material. The duration of protection should be determined in preliminary tests. Until then, an immediately degreasinq of the metal surface should be carried out (especially at copper- and brass-alloys discolorations possible)

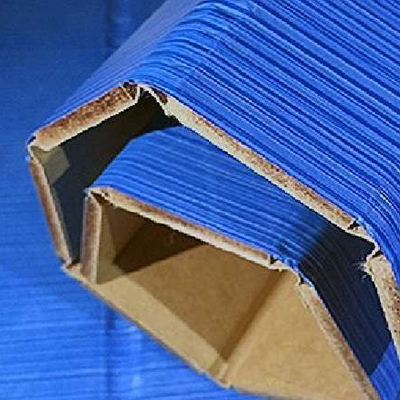

· The removal of the water insoluble oil can be carried out with organic solvents or aqueous, alkaline industrial cleaners by spray- or dipping degreasing plants

Technical data

| Parameter: | Value: | According to: |

| Appearance: | medium brown, clear oil | visual |

| Density at 15℃: | approx. 0.91 g/cm3 | ASTM D 7042 |

| Viscosity at 20℃: | approx. 400-450 mm2/s | ASTM D 7042 |

| Viscosity at 40℃: | approx. 110-130 mm2/s | ASTM D 7042 |

| Flash point: | > 180 ℃ | DIN EN ISO 2592 |

| VKA-value: | n.d. | DIN 51350 T2 |

| Copper-corrosion: | Cu-activity 4 | DIN 51759-1 |

| Reichert-friction-value: | > 1200 kg/cm2 | Reichert-standard |

| Removability: | fulfilled | VDA 230-213 |

Information

Storage must be frost-free between 5-40℃.The minimum durability is 24 months in an original sealed package.

All provided data can vary within conventional technical tolerances, without affecting the product functionality. In regard to the high diversity of the possible application parameters, all information provided under exclusion of any commitment and liability. More safety and environment relevant data can be found in the latest EU safety datasheet.

滬公網(wǎng)安備31011702005477號

滬公網(wǎng)安備31011702005477號